Quality : S235JR – S195T – S275JR – S355JR

Standard: TS EN 10025 – EN 10224 – ASTM A589 – AWWA C200 – SI 103

Outer Diameter : 21.30 – 323.90 mm

Wall Thickness: 2.65 – 6.30 mm

Length : 1-12 m

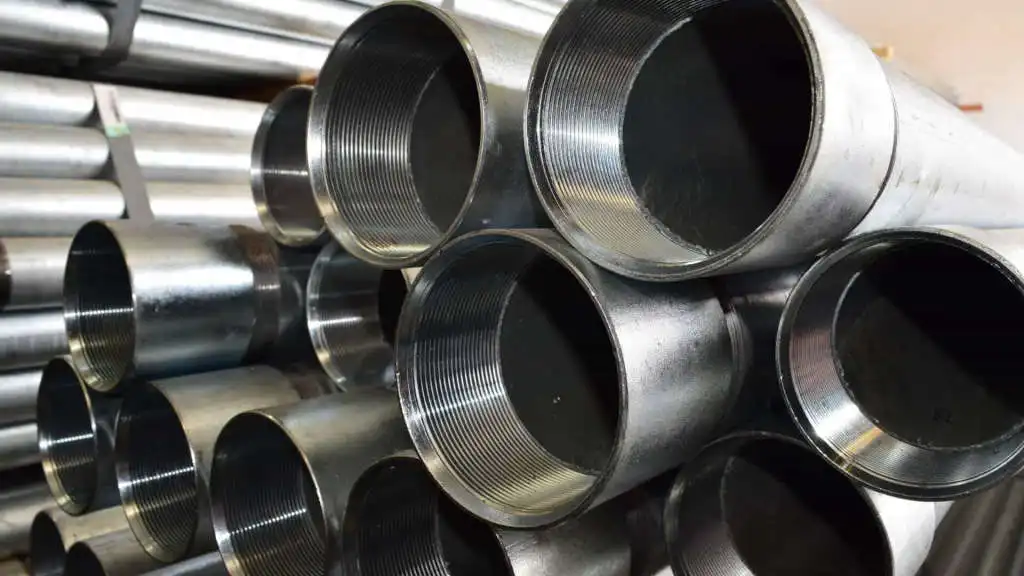

Galvanized Threaded Sleeve Pipe

Also known in the industry as black pipe, galvanized pipe, galvanized threaded sleeve pipe, and tested pipe, Plumbing Pipe is certified by NSF (National Sanitation Foundation) and DVGW (Deutscher Verein des Gas- und Wasserfaches). It is possible to use it in drinking water installations with the help of these certificates obtained in North America and Germany.

One end of our galvanized pipes is threaded, one end is sleeved, one end is capped, and a protective galvanized spray is applied on the threads. In this way, it is protected from corrosion.

Suitability for Surface Coating

The grades produced with the S235JR, S275JR, S355JR notations within the scope of EN 10025-2:2004 standard are designed as Class 1 or Class 3 in accordance with the hot-dip galvanizing method, and other necessary information is given in the quality tables included in the hot products.

Usage areas

– House installations

– Industrial areas

– Major industry projects

– Plumbing areas in the workplace

What Does the Cuff Do?

The question of what the sleeve does, which has an important place for many different installations, is among the topics that are curious. Couplers are generally considered to join 2 pipes together. It is also a threaded installation structure. Thus, it brings together the relevant area more effectively as a connecting pipe. They are the most important parts that allow pipes to be used in many different areas and to be used for many years. Installations both in the industrial area and in the home or workplace are also used in common.

Tests

Our pipes come out of the production lines after passing the tests listed below and EN 10204 2.1; 2.2; 3.1; 3.2 It is delivered with a Material Test Certificate.

• Visual inspection and dimensional inspection

• Leakage Test: Hydrostatic Test, Eddy Current Test

• Destructive Tests: Flattening, Bending, Expanding

• Mechanical Tests

• Chemical analysis

• Metallographic Inspection

• Material Test Certificates

2.1 in EN 10204 standard; 2.2; 3.1; Available on request in 3.2 types

• NDT Standards

ET (EN ISO 10893-2), ET (ASTM E309)

Galvanized Threaded Coupler Pipe Completion Processes

• Flat tip or weld bead

• Thread and sleeve (Max OD: 168.3 mm)

• Grooved

• External protective coating (black or red varnished, other colors available on request) or protective oil application

• Hot-dip galvanizing

• PE, PP Coating

• Bare Pipe (Uncoated)

Production Standards & Steel Grades

|

Standard

|

Quality

|

Outer Diameter Range

|

|

TS EN 10255+A1

|

S195T

|

1/2″ -6″ (21.3mm – 165. 1mm)

|

|

TS EN 10217-1

|

P195 TR1-TR2, P235 TR1-TR2, P265 TR1-TR2

|

21.3 mm-339.7 mm

|

|

ASTM A53 –

ASTM A795

|

GrA, GrB

|

21.3 mm-339.7 mm

|

*They are general production standards.

DIN 17100 St 37-2, St 44, St 52

DIN 17100 Superseeded by DIN EN 10250-1

EN 10025 S195, S235, S275, S355

ASTM Gr A, Gr B

|

Class

|

St 37-2 (S235JR)

|

|

Number

|

1,0037

|

|

Sınıflandırma

|

Non-alloy quality structural steel. According to EN 10250-2: 2000 steel S235JRG2 is also named 1.0038.

|

|

Standart

|

EN 10025-2: 2004 Hot rolled structural steel products. Technical delivery conditions of non-alloy structural steels

|

EN 10025 minimum yield strength in standard ≤ It is applied to materials up to 355 N/mm2 (36.2 kg/mm2). Orders from other grades are taken “subject to negotiation”.

TS EN 10255 All pipes produced in the standard are tested at 50 bar.

Our Water Installation pipes are produced in accordance with UT (EN ISO 10893-11), ET (EN ISO 10893-2) NDT standards in terms of quality.

Quality certificates

Threaded Sleeve Pipe Coating Standards

Galvanized Production Size Range: It can be applied to sizes between 1/2”-6”.

The raw material used contains 99.99% pure zinc.

Galvanizing Norms

Production Standard for Threaded and Coupled Pipes (1/2”-6”) ISO 7/1, ANSI B.1.20.1

Grooving (3/4”-12”) conforming to Victaulic Standard.

Galvanized Water Installation Pipes are produced on the basis of hot-dip galvanized coating. The most critical point for the galvanization coating quality in the hot-dip galvanizing process is whether the pipe raw material is suitable for galvanizing. The ability of steels to get galvanized coating can be understood by looking at the P (Phosphorus) and especially Si (Silicon) values they contain.

|

Classes

|

Elements

|

%

|

by mass

|

|

|

Si

|

Si + 2.5 P

|

P

|

|

Class 1

|

≤ 0,030

|

≤ 0,090

|

–

|

|

Class 2

|

≤ 0,35

|

–

|

–

|

|

Class 3

|

0,14 ≤ Si ≤ 0,25

|

–

|

≤ 0,035

|

Galvanized Production Size Range: It can be applied to sizes between 1/2”-6”.

The raw material used contains 99.99% pure zinc.

Weight Chart

|

Type of material

|

Outer Diameter

|

Wall Thickness

|

Weight of 1 Meter

|

Weight of 6 Meters

|

|

İnç

|

mm

|

mm

|

Kg.

|

Kg.

|

|

1/2″ Galvanized Pipe

|

21,30

|

2,65

|

1,30

|

7,80

|

|

3/4″Galvanized Pipe

|

26,90

|

2,65

|

1,68

|

10,08

|

|

1″Galvanized Pipe

|

33,70

|

3,25

|

2,57

|

15,42

|

|

1.1/4″Galvanized Pipe

|

42,40

|

3,25

|

3,31

|

19,86

|

|

1.1/2″Galvanized Pipe

|

48,30

|

3,25

|

3,81

|

22,86

|

|

2″Galvanized Pipe

|

60,30

|

3,65

|

5,37

|

32,22

|

|

2.1/2″Galvanized Pipe

|

76,10

|

3,65

|

6,89

|

41,34

|

|

3″Galvanized Pipe

|

88,90

|

4,50

|

8,94

|

53,64

|

|

4″Galvanized Pipe

|

114,30

|

4,50

|

12,76

|

76,56

|

|

5″Galvanized Pipe

|

139,70

|

4,85

|

16,50

|

99,00

|

|

6″Galvanized Pipe

|

165,10

|

4,85

|

19,50

|

117,00

|

|

8″Galvanized Pipe

|

219,10

|

5,00

|

27,20

|

163,20

|

|

10″Galvanized Pipe

|

273,00

|

5,60

|

37,30

|

223,80

|

|

12″Galvanized Pipe

|

323,90

|

6,30

|

49,70

|

298,20

|