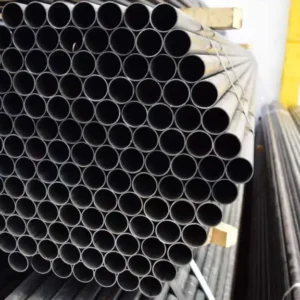

Scaffolding Pipe

What is Scaffolding Pipe?

Scaffolding pipes are components used in the formwork system, steel constructions, and the agricultural sector. Taking into account the floor loads of this system, ridge and grid spacing and telescopic pipe erection distances can be adjusted.

Scaffolding pipes, which have different names such as “telescopic scaffolds, telescopic poles, telescopic poles, iron poles, construction poles, telescopic poles and iron poles”, have different usage patterns. Scaffolding pipes are supported by telescopic pipe struts of 300 – 350 – 400 cm and three legs called tripods.

Scaffolding Pipes meet TS EN 1065 quality standards. Pipes can be used in harmony with other systems. In addition to the pillars, which are the main elements of the system, auxiliary support elements such as Tripod, U Head and Double Way Head are used.

High quality steel bands of DC01 (DIN EN 10130), S185, S235JRH/J0H/J2H, S275J0H/J2H, S355J0H/J2H (DIN EN 10025) quality steel bands in accordance with DIN 2394, TS EN 10305-3, TS EN 10219-2 norms It is manufactured with frequency source (ERW).