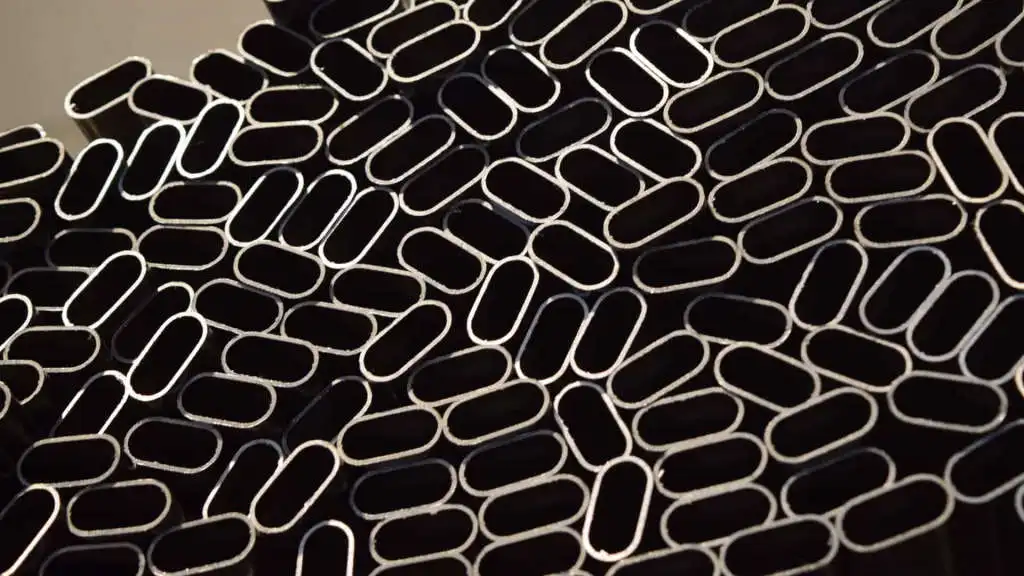

Flat Oval Profiles

Looking at the definition, it is seen that they are made as hollow structural steel products. It is possible to use Flat Oval profiles in mechanical programs and constructions. They are generally known as versatile and this is the biggest advantage that makes them preferred. Oval profile dimensions and oval profile weights varied. There is a reasonable size for every usage area. It is mostly used in decoration and household goods sector.

Features

|

Mechanical Properties

|

|

|

Standard Equivalent

|

ERDEMİR

Quality No.

|

Surface quality

|

Warranty Periods(7)

|

Re(2)(5) N/mm2 (kg/mm2)

max.

|

Rm|1) N/mm2 |kg/mm2)

|

A80|3) |%)

min.

|

r90|4)

min.

|

n90|4)

min.

|

| Flow Trace

Not occurring |

Mechanical

Values |

|

Standard Quality

|

|

EN 10130

|

DC01

|

6112|6)

|

A

|

–

|

–

|

280 |28.6)

|

270-410 |27.5-41.8)

|

28

|

–

|

–

|

|

B

|

3 ay

|

|

EN 10130

|

DC01

|

7612|6)

|

A

|

–

|

–

|

280 |28.6)

|

270-410 |27.5-41.8)

|

28

|

–

|

–

|

|

B

|

3 ay

|

|

EN 10130

|

DC03

|

6113

|

A

|

6 ay

|

6 ay

|

240 |24.5)

|

270-370 |27.5-37,7)

|

34

|

1.3

|

–

|

|

B

|

|

EN 10130

|

DC03

|

7313

|

A

|

6 ay

|

6 ay

|

240

(24.5)

|

270-370 |27.5-37.7)

|

34

|

1.3

|

–

|

|

B

|

|

EN 10130

|

DC04

|

6114|8)

|

A

|

6 ay

|

6 ay

|

210 |21.4)

|

270-350 |27.5-35.7)

|

38

|

1.6

|

0.18

|

|

B

|

|

EN 10130

|

DC05

|

6115|8)

|

A

|

6 ay

|

6 ay

|

180 |18.4)

|

270-330 |27.5-33.7)

|

40

|

1.9

|

0.20

|

|

B

|

Açıklamalar

- Tensile test values are applied to “transverse” test specimens.

- Yield strength values are 20 N/mm2 (2.0 kg/mm2) in the thickness range of 0.5 mm < d 0.7 mm; If d < 0.5 mm thickness, it is increased by 40 N/mm2 (4.1 kg/mm2).

- % elongation values, 2 units in the thickness range of 0.5 mm < d < 0.7 mm; If d < 0.5 mm thickness range, it is reduced by 4 units.

The r90 and n90 values apply to materials with a thickness of 0.5 mm and above.

- For design purposes, the minimum yield strength value is 140 N/mm2 (14.3 kg/mm2).

- For grades with DC01 notation, the upper limit of yield strength of 280 N/mm2 is guaranteed for 8 days starting from the date the material is reported to be manufactured and ready for shipment, and it is recommended to be used within 6 weeks.

- The warranty periods specified in the table begin when the material is reported to be manufactured and ready for shipment.

- It is produced with the “Bulk Annealing” method and only as “A” surface.

Low Carbon Cold Rolled Steels Suitable for Drawing and Deep Drawing Process Standard: EN 10130:2006

|

Chemical Composition (%)

|

|

|

Standard Equivalent

|

ERDEMİR

Quality No

|

C max.

|

P max.

|

Cu

|

S max.

|

Mn max.

|

B

|

Tİ

|

|

Standard

|

Quality

|

|

EN 10130

|

DC01

|

6112

|

0.12

|

0.045

|

–

|

0.045

|

0.60

|

–

|

(5)

|

|

EN 10130

|

DC01

|

7612(1)(2)

|

0.12

|

0.045

|

–

|

0.045

|

0.60

|

20-50

|

–

|

|

EN 10130

|

DC03

|

6113

|

0.10

|

0.035

|

–

|

0.035

|

0.45

|

–

|

(5)

|

|

EN 10130

|

DC03

|

7313

|

0.10

|

0.035

|

–

|

0.035

|

0.45

|

–

|

(5)

|

|

EN 10130

|

DC04

|

6114

|

0.08

|

0.030

|

–

|

0.030

|

0.40

|

–

|

(5)

|

|

EN 10130

|

DC05

|

6115

|

0.06

|

0.025

|

–

|

0.025

|

0.35

|

–

|

(5)

|

Descriptions

- Suitable for electric resistance welding.

- It is produced with B addition.

- DC03, DC04, DC05 grades are produced as fully stagnant. Therefore, the Al/N ratio is at least 2:1.

- The limits indicated in red are the standard limits, and the other limits are the values given as a reference according to Erdemir practices.

- It can be produced with the addition of Ti.

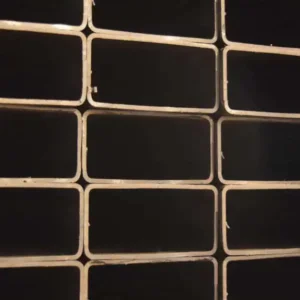

Usage areas

Along with their different productions, there are many usage areas in building profiles. It is used in different areas according to its carrying capacity, various sizes and dimensions. One of the leading areas is steel construction buildings, the construction of factory buildings, industrial buildings and various multi-storey residences.

In areas such as business centers and shopping centers, the use of building profiles is also common in many areas for durability. One of the areas where the building profile is used is ceilings. Light steel truss is also used in areas such as roofs and ceilings.