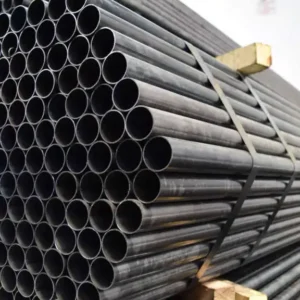

Boiler And High Pressure Pipe

What is Boiler and High Pressure Pipe?

The production of our pipes, which are also known as boiler pipe, steam pipe, high temperature pipe and high pressure pipe, are made in accordance with the sectoral standards and quality requirements demanded by our customers. It is possible to use as an alternative to drawn steel pipes.

Our boiler and high pressure pipes are produced in accordance with UT (EN ISO 10893-11), ET (EN ISO 10893-2) NDT standards, having AD-2000 WO, AD-2000 W4, PED quality certificates.

We deliver our boiler pipes with alternatives such as flat end or welded end, uncoated, factory protective coating on the outer surface (black varnished) in the finishing procedures.

Our boiler and high-pressure pipes pass the tests listed below and exit our production lines and comply with EN 10204 2.1; 2.2; 3.1; 3.2 Material Test Certificates; PED Certified Pressure Equipment Directive 2014/68/eu Certified.

Tests Performed

- Visual inspection and dimensional inspection

- Mechanical Tests: Tensile Test, Flattening Test, Flaring Test, Expansion Test

- Metallographic Inspection

- Chemical analysis

- Hydrostatic Test

- Non-Destructive Testing: Online Ultrasonic (Welding Control),

- Eddy Current