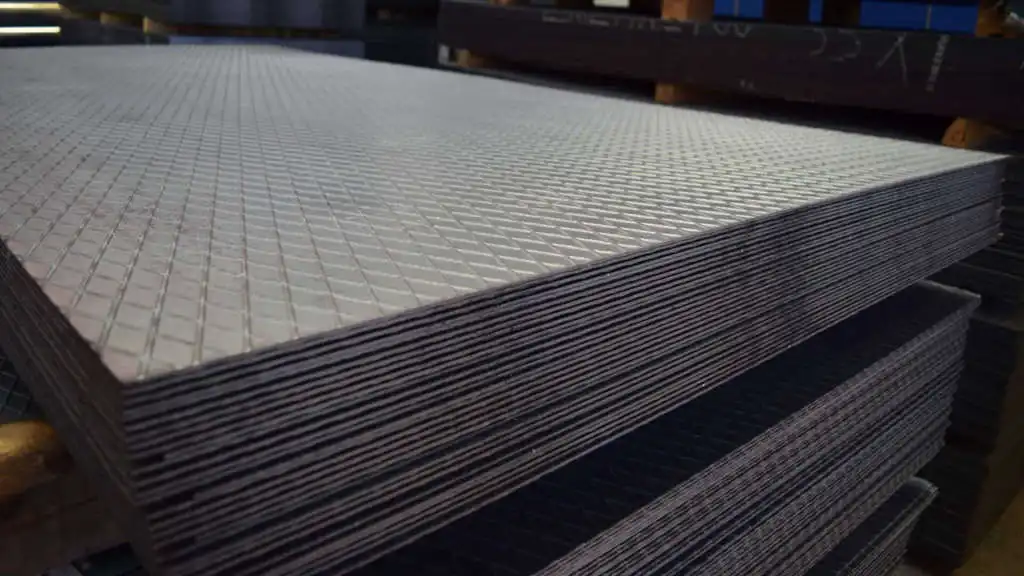

Checkered Sheet

They are products formed with lozenge patterns, which are called Checkered Sheet.

Checkered sheets are designed as an alternative to plain black sheets. Checkered sheet, which has many uses, is often preferred for steps. In addition to its wide usage area, the most important reason why it is mostly preferred for stair steps is its feature to prevent people from slipping and falling with the help of its serrated surface. Another important advantage of checkered plate is that it is more durable when compared to plain black steel in terms of strength resistance.

Checkered sheets can show dimensional changes according to the wishes of the people. In addition to these, there are some generally accepted standards in the world. The products produced according to these standards are distinguished from other sheets in terms of their quality and durability and provide customer satisfaction.

If we talk about these standards briefly, the wall thickness of the sheets is 0.50 mm. and 1.00 mm. must be in the range. Its length can be between 1000 mm and 12.000 mm. In addition, it can be up to 20.00 mm according to the needs of these customers.

The usage areas of the diamond-patterned sheets are more or less the same as the other sheets. It is used in the exterior coatings of warehouses and warehouses, houses, garages, automotive industry, etc. used in many fields.

Their quality

|

Chemical Composition (%)

|

|

Standard Equivalent

|

ERDEMİR

|

C

|

Mn

|

P max.

|

S max.

|

Si max.

|

Cu max.

|

N4

|

CE(IIW)(6) max. (%)

|

|

Standard

|

Quality

|

Quality No

|

max.

|

max.

|

max.

|

|

EN 10025-2

|

S235JR+AR Special

|

3235(2)

|

0,17

|

1,4

|

0.035

|

0.035

|

0,4

|

0,55

|

0.012

|

0,35

|

|

EN 10025-2

|

S275JR+AR Special CTB

|

3243(3(7(9

|

0.14-0.20

|

1.00 – 1.35

|

0.025

|

0.025

|

0.15 – 0.25

|

0,55

|

0.012

|

0,4

|

|

EN 10025-2

|

S235JR+AR CTA

|

4275811)

|

0,17

|

1,2

|

0.025

|

0.035

|

0,03

|

0,55

|

0.012

|

0,35

|

|

EN 10025-2

|

S235J2S235J2+N CTA

|

4239(5(8)

|

0,17

|

1,4

|

0.025

|

0.025

|

0,03

|

0,55

|

|

0,35

|

|

EN 10025-2

|

S275J2

|

4246(5)7

|

0,18

|

1,5

|

0.025

|

0.025

|

–

|

0,55

|

|

0,4

|

Descriptions

1) The quality specified in this table is produced in İsdemir facilities within the framework of agreements made with customers.

2) In this quality, it is produced in such a way that there is no roll breakage.

3) Mechanical testing is not done according to production practices.

4) In the chemical composition of the steel, min. For grades with 0.020% Al, the upper limit value of N is not applied.

5) These grades are produced as fully stagnant and have a minimum Al/N ratio of 2:1.

6) Carbon equivalent is calculated according to the formula CEV (IIW) % = C + Mn / 6 + (Cr + Mo + V) / 5 + (Ni + Cu) / 15.

7) For S275 and S355 grades, max. carbon equivalent (CEV) is increased by 0.02% for %Si ≤ 0.04 and 0.01% for %Si ≤ 0.25.

8) It is suitable for galvanized coating as “Category A”. Si ≤ 0.030% and Si+2.5P ≤ 0.090% limits apply in Category A class

9) It is suitable for galvanized coating as “Category B”. Si 0.14≤ Si ≤0.25% limit is applied in Category B class.

10) In line with the production practices, the suitability for galvanized coating can be considered subject to negotiation at the order stage. Classes of suitability for galvanized coating Category A

Si ≤ 0.030% and Si+2.5P ≤ 0.090% limit in Class B, Si 0.14≤ Si ≤0.25% limit in Category B class, Si 0.25< Si ≤0.35% limit in Category D class.

11) Max. It is produced up to 8 mm thickness.

Usage areas

The usage area is as wide as possible thanks to the pattern of the checkered sheet, its durability and the possibility of using it reliably. Its decorative appearance leads people to prefer to use checkered plate on floors and walls. Another important area of use is fire escapes, walkways and ramps with the help of its rough surface. Thus, even if there are dangerous conditions such as wet floors, people can pass on these floors without slipping and no safety problems arise.