LASER CUTTING

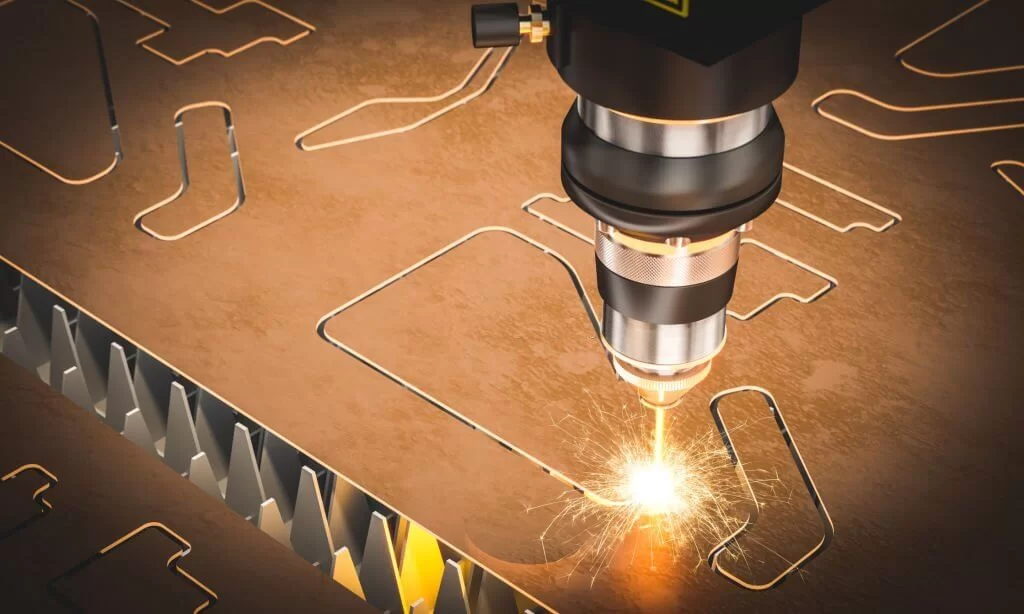

We use the laser cutting method in profile iron and sheet metal cutting processes. Thus, we obtain fast and economical solutions. Before we explain all the cutting processes we do with the laser machine in detail, let’s start by explaining what the concept of laser cutting is.

What is Laser Cutting?

It is the reflection of the rays in the plasma state by means of optical mirrors and the realization of burning and cutting processes. There are machines that do this job and they are specially designed.

Laser cutting machine is called Computerized CNC.

The process process is the excitation of electrical resonances in a sealed container to produce laser beams. It performs the excitation process for the materials to shine. As a result of this process, the rays that accumulate enough energy to escape are reflected to the external environment with the help of optical mirrors. The important thing here is that these rays are reflected by focusing in a narrow area. This is what makes cutting or other processes effective.

The diameter of the rays coming out of the machine is 1.5-2.0 millimeters thick. The beam material in the lens head is used to focus the rays. With the help of lenses and mirrors located between the beams, laser beams are focused on very small points such as 0.025 millimeters.

In sheet metal cutting, the focusing range is 38-76 millimeters. The focus range changes depending on the type of material to be cut. This change is carried out with the help of CNC machines.

Laser Cutting Parameters

Laser cutting parameters differ according to the type of metal. Based on the metal type, the cutting speed and gas amounts are adjusted with the help of machines. For example, nitrogen gas is used for stainless steels. Oxygen gas is used for cutting mild steel metals.

Likewise, nitrogen or nitrogen gas is used for cutting aluminum metal materials.

Advantages of Laser Cutting Process

When the cutting process applied to metals is done with the laser method, you gain the following advantages:

- You save time and money.

- It reduces production costs.

- There is no limit in production. You can cut any size you want.

- Fire rate decreases.

- More work occurs per unit time.

- You will not encounter any problems during the cutting process.

Types of Laser Cutting

Evaporation, melting and processing, reactive cutting methods constitute the types of laser cutting. Let us briefly introduce these types.

Evaporation Method

This process is standard in laser cutting applications. In other words, it is a method used in all metal materials.

The evaporation method is to focus the laser beams on a point and create heat at boiling point in this region.

The material heated at the boiling point begins to melt and a keyhole-like cavity is formed in this part.

Melting Processing

Also called fusion or pulse cutting. In this method, high pressure gas is applied to the cutting area of metals. Thus, more power usage is prevented. The material is heated to the melting point with laser beams. The gas is then sprayed. Compressed gas expels the material in this area outwards.

Reactive Cutting Method

It is also called laser cutting gas. In the reactive cutting process, the ignition source is laser beams. Just like in the oxygen source, that is, a laser beam is created in the form of a torch flame and applied to the surface of the metals. This method is generally used to cut carbon steels thicker than 1 millimeter. Steel plates are also cut with this method by applying less laser beam.

How Is Laser Cut Sheet Metal Processed?

First of all, the thickness of the sheet material to be cut is measured. The photo of the material is then uploaded to the CAD software that drives the CNC machine. Vector drawing is created. Laser cut sheet metal placement is performed.

The metal to be cut is placed on the table of the CNC machine. Gas selection and parameters suitable for the sheet material to be cut are determined.

Finally, the cutting process is started and terminated.

Laser Cut Sheet Models

We can cut the thickness and shape you want. You can reach us at our contact addresses for laser cut sheet metal models and more.

Laser Cut Sheet Prices

We determine our prices depending on the duration of the process and the amount of material to be cut. When receiving laser cutting prices from our customer consultants, be sure to submit the necessary information completely.

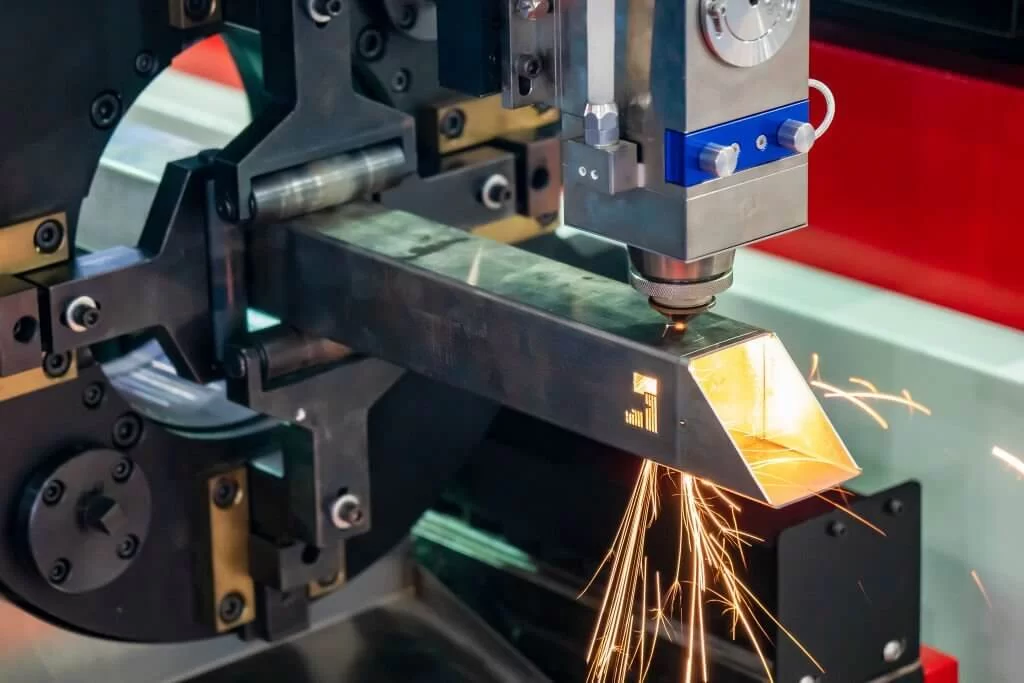

Pipe Profile Laser Cutting

In this cutting process, we take care that there is no residue on the surfaces of the steel profile pipes. After thoroughly cleaning the surfaces, we separate the profiles according to their lengths. Then we start the cutting process according to the following methods.

Oxy Profile Cutting

It is a type of cutting that we perform with the help of laser machines that produce plasma. This method is ideal for cutting, as profile materials are not affected by high temperatures. It is the type of cutting we perform using oxygen gas and laser beams.

Plasma Profile Cutting

The laser cutting work performed with this method saves money and time. It is performed on the CNC machine by creating pressurized gas and laser beams. The error level is minimal. With this method, we perform fast cutting operations. Thanks to the professional laser cutter, the process is completed perfectly.

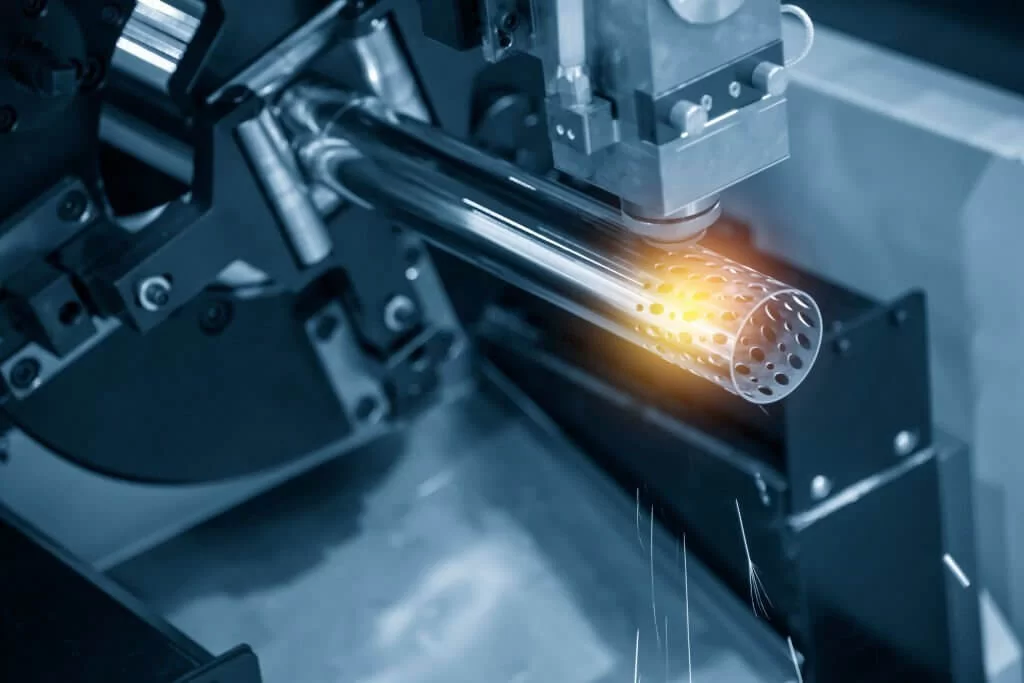

Contract Laser Pipe Cutting

Apart from the processes we carry out as a standard, we also perform contract laser pipe cutting.

We perform cutting in the shapes and sizes you want. Please call us for detailed information about laser cutter and cutting processes.

Profile Laser Cutting Ankara

In the province of Ankara, which is our field of activity, we perform the fast and clean cutting operations you need. Your orders are ready in a short time!

You can find more detailed information about our profile laser cutting Ankara services on the home page of our website.

We get help from the best laser cutter personnel.

What is CNC Laser Cutting?

In machines called CNC; There are sections such as processing table, computer, operator area. The cutting operations performed with the help of this machine and the laser connected to this machine are called CNC laser cutting .

Laser cutter is the person who operates this machine. The laser cutter also determines the surface to be cut with the help of a computer program.

What is CO2 Laser Cutting?

Some gases are used in laser cutting of metals. One of these gases is carbon dioxide gas.

High-intensity laser beams are obtained with the help of lenses and mirrors in the laser unit located in the head area of the CNC machine. With the help of these laser beams, high temperatures are created on the metal surface. In the arrangement of this melting surface, carbon dioxide gas is assisted.

In other words, carbon dioxide gas cleans the debris formed in the areas cut by the laser beams.

The laser cutter is the person who manages all these processes.

In Which Sectors Is Laser Cutting Used?

Laser cutting sheet metal, pipe cutting and carbon steels meet the needs of the industry and construction industry.

Laser cutter meets the needs of the following areas:

- Construction industry,

- Crane industry,

- Yacht and shipping industry,

- Advertising industry and

- All kinds of architecture and engineering fields

Types of Laser Cutting Machines

Bench types also differ according to the type of material to be cut. However, three different types of countertops are generally used in the market.

CO2 machine for traditional cuts, fiber laser machines for new generation cutting processes and diode laser machines using DDL technology…

All kinds of metal cutting operations, especially laser pipe cutting, are carried out in these three different bench or table areas.

A laser cutter is the person who cuts on all machines.

Laser Cutting Prices

Laser cutter prices are determined according to criteria such as the machine used, the type of material, the processing time and the number of materials. Make sure to call us to get clear price information according to the type of transaction you want to make.

Laser Cut Price Calculation

By entering criteria such as unit cost of electricity, unit cost of spent gas, labor and materials, you can calculate the average laser cutter prices. For detailed information, just call us.

Our customer consultants will perform laser cutting price calculations in a short time with the information they receive from you.

You can also call us and get detailed information about the laser cutting machine and other issues.