CNC CUTTING

The abbreviation of Computer Numerical Control refers to the concept of CNC. CNC cutting is the cutting operations made with this machine.

What is CNC Cutting?

It is the name of the type of cutting performed with the help of a machine called CNC. The CNC machine is actually also used for different services in different industries. In the metal cutting area, the cutting process is carried out by the combustion reaction of gases and using a laser.

In the CNC cutting process, assistance is taken from the computer software that is connected to the machine. Thanks to the software, the cutting shapes and sizes of the metal to be cut, whose 3D image is created, are determined.

What is CNC Cutting Machine?

The ancestor of this machine was lathes. In many workshops in our country and around the world, cutting and trimming operations were carried out on lathes.

With the development of trade and the increase in business volume, lathes began to be insufficient.

By utilizing the possibilities of technology, an advanced turning machine called CNC was invented. This machine; It consisted of parts such as the workbench, the head that did the cutting or other operations, and the computer.

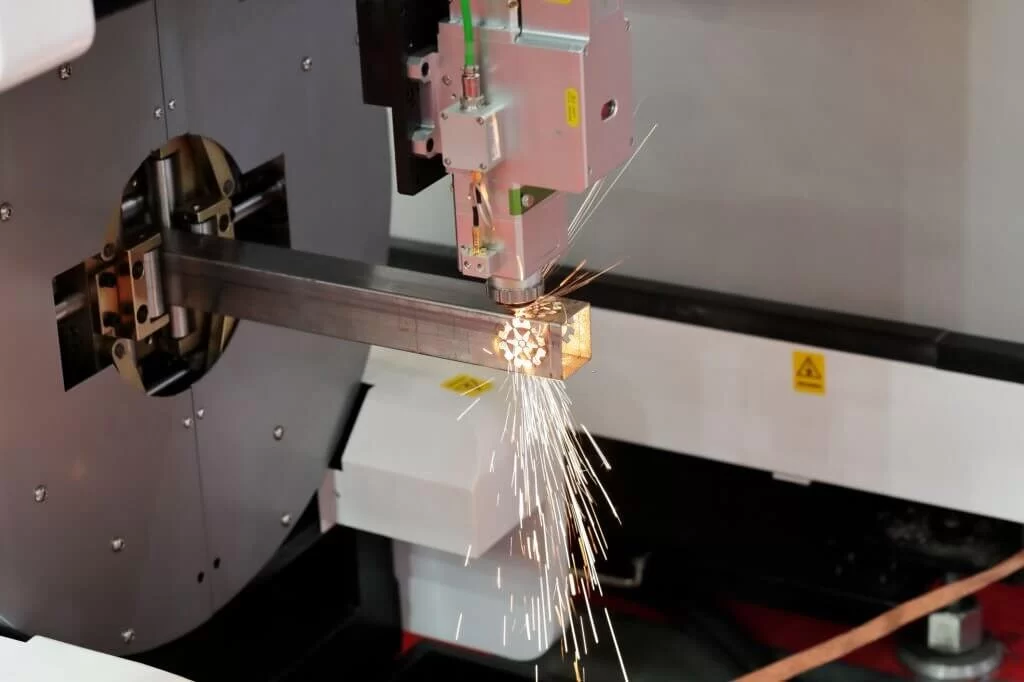

In the future, versions capable of laser cutting were also produced. Today, the most advanced CNC cutting machine is the one that works with laser beams.

What is CNC Laser Cutting Machine?

CNC machine models have been produced that can effectively use concentrated laser beams and some gases. The bench of these machines was different from other models. The workbench was completely dependent on computer commands.

The fixed metals are cut on the Laser CNC machine with the command coming from the computer.

The machine works with laser power between 500 W-4000 W. The table and the head are a whole. The head is designed to be vertical to the table and to reach all parts of the table. There is a computer on one side and a cutting laser head on the other.

What are CNC Cutting Types?

CNC laser cutting types are classified according to the type of gas and laser used. The types of CNC cutting are briefly explained below.

Cutting with CO2

Carbon dioxide gas is reacted with high voltage electricity. This creates a laser beam.

Neodymium Laser Cutting

Different gases produce different laser beams. In this case, the severity and quality of the cut also changes. Laser beam is obtained as a result of the electrical reaction of a gas called neodymium under high pressure.

Fiber Laser Cutting

It is the most advanced CNC cutting type. In this new technology, fiber technology has been added to neodymium technology. Thanks to the fiber material, the sensitivity of the laser beams becomes greater. This technology is used in all metal cuttings that require fine workmanship.

Oxygen Cutting

CNC cutting types are one of the operations. The metal material with the oxygen gas is reacted with electrical energy. A large amount of heat energy is produced. The heat energy is sufficient to melt the metal surfaces.

Oxygen causes the metal to burn. The amount of melting in the oxides is limited and it is ensured that it is less than that of the metal. CNC cutting machine ensures that the oxides have a fluid structure.

Plasma Cutting

The direct current electrical source ionizes the compressed air produced inside the machine. Thus, plasma energy is released. Cutting is also carried out with the help of conductive materials.

This type of cut can be applied to all conductive metal materials. It allows to make very high quality cuts between CNC cutting processes.

It allows the processing of different metal parts on the machine bench. It allows saving with the least amount of wastage.

Thanks to this cutting technique, smooth and neat cuts can be achieved with very little burrs.

More cutting operations can be performed per unit time.

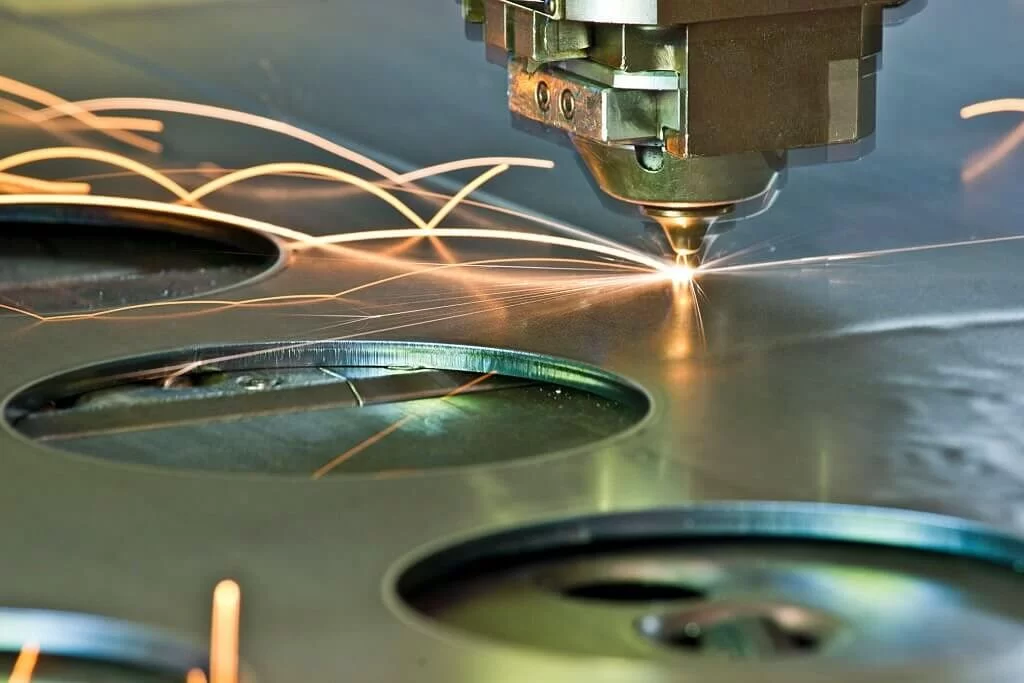

Laser Cut

CNC laser is the latest technology used today. It started to be used with fiber technology. In this way, more accurate cuts can be realized in a very short time.

A laser beam is obtained by reacting some gases with electrical energy. These laser beams are directed to metal surfaces with the help of optical lenses and mirrors. Just like focusing sunlight on a surface with the help of lenses and obtaining heat energy…

The laser obtained in this way focuses on a point and a high rate of heat energy is generated. This heat energy creates the temperatures at the boiling point of metals.

Laser beams focused on the metal surface cause the material to melt and even evaporate. With the help of oxygen and carbon dioxide gases, the burrs formed on the melting surface are removed from the surface.

Laser Cutting:

- Thermal stretching,

- Silicon fluidity and

- Reactive cut

Such methods are used.

What are the Advantages of CNC Cutting?

Below are the advantages that can be obtained when using CNC cutting:

- It eliminates the cost of mold in part manufacturing.

- It enables more cutting operations to be performed in a short time.

- It saves time and money.

- Minimum level of fire is given.

- It allows high quality cuts to be made.

- Nearly no deformations occur during cutting.

Where is CNC Cutting Used?

Cutting operations are most needed in the industrial sector. Secondly, cutting processes are preferred in the construction sector. CNC cutting process is needed in cutting the parts required for shipbuilding and cutting metal materials required for crane construction.

CNC Cutting Prices

As in other cutting operations, in cutting operations performed with the help of CNC machine:

- The number of materials to be cut,

- The type of action to be taken and

- Duration

According to such information, CNC cutting prices are determined. In order to get clear price information, you should contact us through the communication channels on our website. After giving the necessary information to our customer advisors, you can access the net price information.